Contract crushing is an opportunity to effectively solve production tasks using modern equipment (without the need to purchase it) and highly qualified personnel.

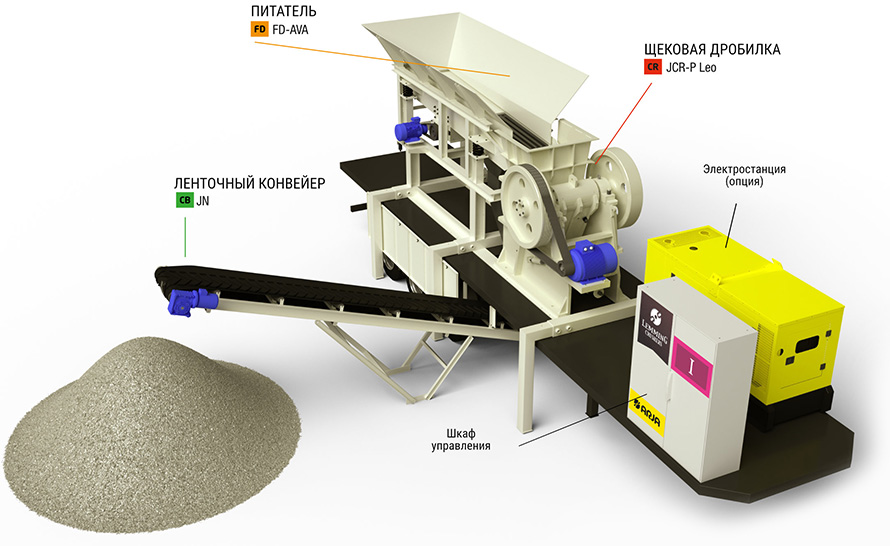

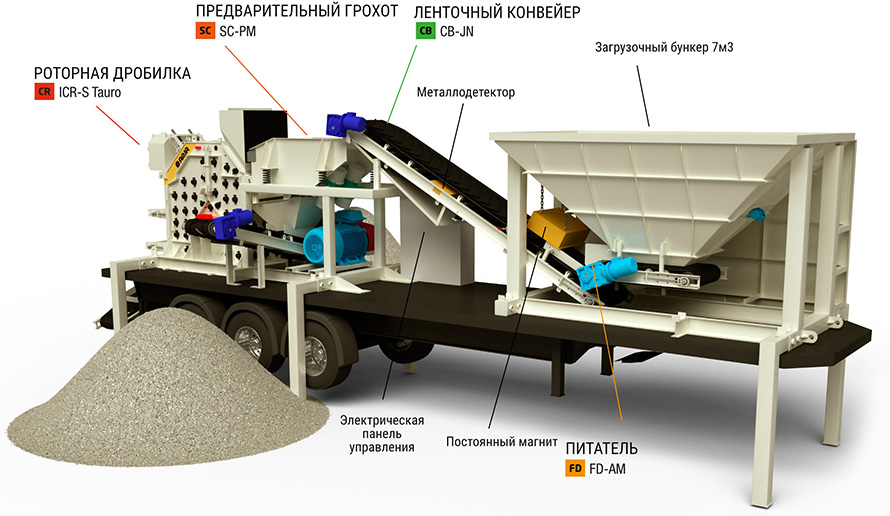

The emergence of a new service from "Rudprom" was driven by the desire to reduce clients' production costs while maintaining the quality of the final product. In their work, the company's specialists use efficient, modern equipment with high efficiency – ARJA crushing and screening complexes. The installations are equipped with jaw and rotor crushers.

• Thanks to the "DINAFLOW" system along with the horizontal shaft impact crushing system, the inertia generated by its movement is used to produce electricity, thus reducing energy consumption.

• The highest motor efficiency is ensured by the built-in frequency converter, allowing at the same time to maintain the perfect granulometric curve.

• Complete movement is carried out without the need for transport vehicles and/or special devices.

• The system is equipped with a pre-screen before the crusher to optimize the chamber and significantly reduce wear by eliminating fine particles. There is also a bypass system to use fractions if they are found suitable.

• The Tauro impact crusher line is characterized by high versatility, allowing the production of a large number of fractions with minimal settings, providing maximum productivity and maintaining optimal cubicity.

• Our impact crushing equipment is equipped with a serial metal detector and a permanent magnet for comprehensive equipment protection, preventing metal elements and non-crushable items from entering the chamber.

• The components of the crusher that are most prone to wear will be made of ceramic alloy material.

• The receiving hopper is made of 6 mm sheet steel and a frame with cross ribs for securing on all sides.

• It also has a grid on top to prevent the accidental entry of oversized material. The equipment provides for the pre-installation of a watering system to eliminate dust.

• An additional feature is the App Vijeo Design’Air smartphone application.

• The equipment is equipped with a watering system to eliminate dust.

• The safety and protection systems comply with European standards, with a limit switch installed on the access door to the chamber that cuts off the power supply to the motor. Additionally, the bolt that allows the doors to be opened is designed to lock the rotor to prevent accidental capture.

• The crusher is equipped with 4 telescopic legs via a hydraulic system.

• To ensure the highest quality of the finished product, all components have been carefully selected to be the best on the market (bearings, cast elements, electrical materials, etc.)

• Complete movement occurs without the need for transport vehicles and/or special devices, furthermore, the equipment is fully autonomous, thanks to the integrated generator set, which is an integral part of the equipment.

• High efficiency in aggregate processing is achieved thanks to the Grizzly vibrating feeder equipped with a frequency-controlled drive for better process control.

• AVA vibrating feeders are characterized by high durability and tray attachment, in addition to their easy disassembly and maintenance. The grizzly grid is made according to the quarry's specifics.

• Thanks to the "NO-CLOG" anti-clogging system, the power control algorithm activates the rotation moment at maximum power sequentially in one direction, then in the other, until the blocking element is eliminated.

• Engine performance and energy consumption reduction are achieved through the frequency converter.

• The crusher is equipped with a system of protective springs to prevent accidental entry of metals or non-crushable elements. The centralized system for equipment adjustment and control is carried out via an electronic tablet through a programmable automatic setup.

• LEO jaw crushers consist of an electrically welded steel frame mounted on four two-row roller bearings, balanced flywheels, jaws made of 14/16% manganese steel alloy, a hydraulic opening and closing system, and a centralized lubrication system. All this provides high reliability and efficiency.

• The Geminis impact crusher series is designed for ballast production, waste recycling, and small fraction production. High loading capacity (up to 650 mm). Versatile primary/secondary impact crushers.

• An additional feature is the App Vijeo Design’Air smartphone application.

• The crusher is equipped with 4 telescopic legs via a hydraulic system.

• To ensure the highest quality of the finished product, all components have been carefully selected to be the best on the market (bearings, cast elements, electrical materials, etc.)

Our company successfully implements projects throughout Russia, the CIS countries, Europe, and Africa. The priority areas of activity are solving production tasks in the fields of ore and non-ore industries, processing metallurgical slag, and construction waste. In particular, "Rudprom" specialists:

• ensure a full production cycle, including at the processing stage;

• work in various conditions, regardless of their complexity;

• strictly adhere to safety rules;

• cooperate with leading manufacturers of mining equipment;

• guarantee the mobility of the systems used, their quick integration, and disassembly at the customer's site.

Clients of the company can rent high-performance crushing installations, which guaranteedly increase the volume and quality of processed material.

In addition, qualified "Rudprom" specialists provide full informational and technical support, allowing complex production tasks to be successfully solved. As a result, the client gets an excellent outcome, optimizing work processes since they do not pay for equipment maintenance. These costs are borne by "Rudprom".

Use the services of professionals.