The jaw crusher is the oldest crushing machine. Its simple and effective mechanism crushes materials with two "jaws." One of the most popular brands in the crushing equipment segment is the SMD jaw crusher (Stationary Crushing Machine). The SMD crusher is considered the most economical since its working surfaces wear less compared to other types of crushers.

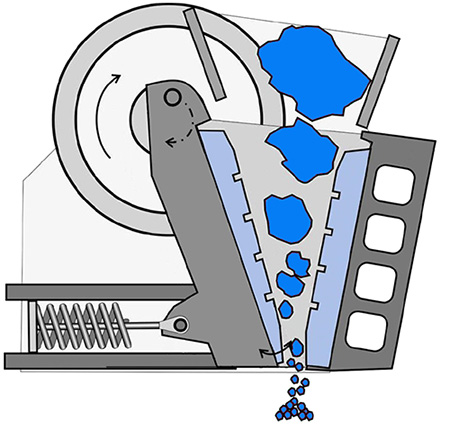

Here is the diagram of a jaw crusher with simple jaw movement. The wedge-shaped crushing chamber is formed by one stationary jaw and one swinging jaw, which is fixed at one end on a crank mechanism. The drum rotation causes the jaw to swing, with the wedge uniformly widening and narrowing, crushing the material. As the material is crushed, it falls downward and is further crushed, continuing the process. The output product is no larger than the size set by the distance between the jaws at the bottom. The largest jaw crushers can handle boulders up to a meter in diameter, while the smallest crushers can produce material as small as 1 cm in diameter.

It would seem that after 150 years, the design of the jaw crusher has been optimized. Its mechanism requires little maintenance, with only a few components needing periodic lubrication. However, even today, the jaw crusher continues to improve. Modern jaw crushers are equipped with a frequency converter — a mini-computer that helps save electricity, protects the motor from overheating, and prevents start-up overloads. These converters are sometimes referred to as "soft starters." Not long ago, these devices were used only in the defense industry. In the relatively conservative production of crushing and sorting equipment, they represent an innovation.

Jaw crushers are simple, reliable, compact, efficient, and stable. Depending on the material they are designed for, jaw crushers come with simple and complex jaw movements, as well as with standard and reinforced frames.

Jaw crushers are well-suited for processing relatively brittle materials with a compressive strength ranging from 300 to 500 MPa and can handle highly abrasive materials. The primary purpose of jaw crushers is to process rocks like basalt, gabbro, granite, diabase, dolerite, dolomite, marble, and others.

For each type of material and feed size, Rudprom offers specially designed crushers manufactured by leading crushing equipment factories, including Kanmash and DSP Přerov.

| Equipment Name | Type | Maximum Feed Piece Size, mm | Discharge Gap Width, mm | Capacity, m³/h | Nominal Drive Power, kW | Weight, kg |

|---|---|---|---|---|---|---|

| SMD-508 | SHDS-1.6x2.5 | 130mm | 30mm | 3,3m³/h | 7,5kW | 1500kg |

| DSh-2.5x4 (full analogue of SMD-116) | SHDS-2.5x4 | 210mm | 20 ÷ 80 | 4 ÷ 16 | 18,5kW | 2800kg |

| DSh-2.5x9 (full analogue of SMD-108A) | SHDS-2.5x9 | 210mm | 25 ÷ 60 | 15 ÷ 31 | 45kW | 8400kg |

| DSh-4x9 (full analogue of SMD-109A) | SHDS-4x9 | 340mm | 40 ÷ 90 | 23 ÷ 53 | 45kW | 10800kg |

| DSh-6x9 (full analogue of SMD-110A) | SHDS-6x9 | 500mm | 75 ÷ 130 | 58 ÷ 104 | 75kW | 18700kg |

| DSh-8x10 (full analogue of DRO-609A) | SHDS-8x10 | 680mm | 100 ÷ 180 | 85 ÷ 155 | 132kW | 28000kg |

| DSh-9x11 | SHDS-9x11 | 770mm | 150 ÷ 250 | up to 170m³/h | 110kW | 29000kg |

| DSh-11x12 | SHDS-11x12 | 950mm | 150 ÷ 300 | up to 210m³/h | 132kW | 42000kg |

| DSh-13x15 | SHDS-13x15 | 1100mm | 150 ÷ 300 | up to 270m³/h | 160kW | 60000kg |

| DSh-9x12 SMD-111B | SHDP-9x12 | 750mm | 95 ÷ 190 | 180m³/h | 90kW | 54000kg |

| SMD-118B | SHDP-12x15 | 1000mm | 115 ÷ 195 | 310m³/h | 160kW | 113000kg |

| SMD-117B | SHDS-15x21 | 1300mm | 135 ÷ 225 | 600m³/h | 250kW | 201800kg |

Leave a request, and our specialists will assist you shortly